Cleanroom Vacuums

Captures up to 99.999% of ultra-fine particles down to 0.12 microns

Cleanroom Vacuums

CleanRoom vacuums are suitable for the pharmaceutical, chemical, cosmetics, food, electronics, laser or packaging sectors. They are all equipped with HEPA or ULPA filters, they are quiet and easy to clean.

breadcrumb >> list

Nilfisk Single-Phase CleanRoom Vacuum Cleaners

GM80CR GMPJ 110-120V ULPA

Lightweight and portable, the Nilfisk GM 80P symbolizes Nilfisk quality and provides durability, high performance and efficient cleaning – required by dust control professionals.

The sturdy aluminum canister makes it almost indestructible and especially suitable for rough and heavy-duty cleaning.

Mounted on a strong steel trolley with large rubber wheels, the machine is easy to manoeuvre. Ideal for cleanrooms in the chemical, pharmaceutical, food & beverage, and cosmetics industries, hospitals and offices.

GM 80P is a versatile machine with high suction power and can be used for both industry cleaning and integrated into production facilities. The unique multi-stage filtration system allows for adaption to special applications where high filtration level and low emission is required. Choose between two types of dust bags (fleece or paper), four different washable sack filters (Polyester, Cotton, PTFE or Nomex) and special exhaust filters with ULPA classification. GM 80P can handle every heavy-duty cleaning task and has become a vacuum cleaner icon in variety of industries.

See brochure below

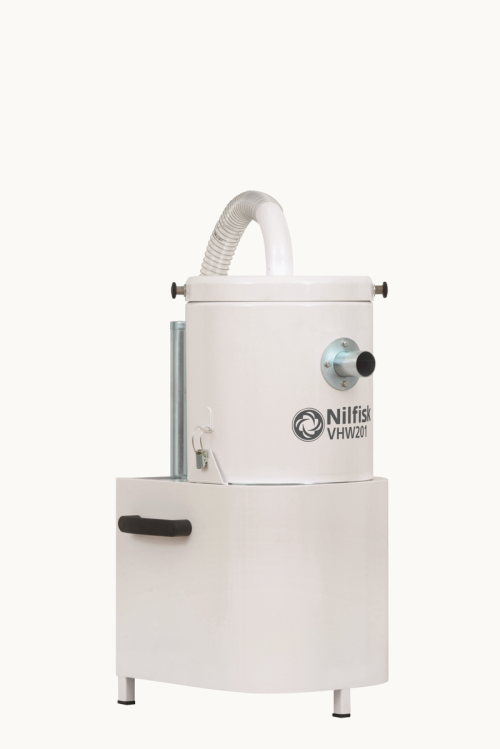

VHW211

The VHW211 has a small 18×17 inch foot print to easily fit wherever space is at a premium. Ideal for automated systems, the VHW211 can switched on manually, or be hard-wired to process machine to provide suction for a variety of applications. Maintenance and clean-up is extremely easy with a removable top cover to access the main filter without direct contact with the debris.

The VHW211 is built in a vertical configuration with a fully enclosed chassis to make clean up easy. Intended to be stationary, it can be fitted with optional swivel casters if necessary. The 0.95 kW side channel blower delivers continuous performance and long term reliability while providing 64″ of pressure and 102 cfm. It is also available in single phase models and all are equipped with a pressure relief valve to help extend motor life. An optional HEPA or ULPA filter can be mounted upstream, downstream or both for optimal filtration and operator safety. The downstream option will increase the overall height to just over 36 inches. Maintenance and clean-up is extremely easy with a removable top cover to access the upstream HEPA or ULPA and shake the main filter without direct contact with the debris. The collection container is completely removable from the base for filter replacement, cleaning and sanitizing.

Nilfisk 3-Phase CleanRoom Vacuum Cleaners

VHW320-InfiniClean

The VHW320 InfiniClean delivers the features and performance of the VHW321, but with continual, automated filter cleaning. It is the perfect solution when collecting fine dry dusts in a production process without the need to stop the machine.

The VHW320 IC continuous duty vacuum is fully prepared to go to work, with a manometer, motor starter and fully enclosed chassis. The main filters are cleaned on a continuous cycle while the machine is running, using the vacuum’s own exhaust air to reverse purge the cartridges. With more than 16 sq ft of surface area, filtration is optimized and the standard downstream HEPA or optional ULPA filters further protect operators from harmful dust exposure. The standard manometer indicates when the main filters need replacement, taking the guesswork out of service intervals. A manual motor starter is also standard, highly visible and easy to use.

- Continuous duty, 2.0 kW side channel blower

- 6.6 gallon collection container

- Three conical cartridge main filters

VHW420

The VHW420 delivers full feature, continuous duty operation and excellent filtration and performance for housekeeping and maintenance, or as part of a production process.

The VHW420 continuous duty vacuum is fully prepared to go to work, with a manometer, motor starter and fully enclosed chassis. The main filters are cleaned using the PullClean system that applies differential air pressure to reverse purge the cartridges without the need for an external compressed air source. With 21.5 sq ft of surface area, filtration is optimized and upstream and or downstream HEPA or ULPA filters further protect operators from harmful dust exposure. The standard manometer indicates when the main filters needs cleaning, taking the guesswork out of service intervals. A manual motor starter is also standard, highly visible and easy to use.

- Continuous duty, 2.6 kW side channel blower

- 12.2 gallon collection container

- Four conical cartridge filters

VHW440

The VHW440 delivers full feature, continuous duty operation and excellent filtration and performance for housekeeping and maintenance, or as part of a production process.

The VHW440 continuous duty vacuum is fully prepared to go to work, with a manometer, motor starter and fully enclosed chassis. The main filters are cleaned using the PullClean system that applies differential air pressure to reverse purge the cartridges without the need for an external compressed air source. With 21.5 sq ft of surface area, filtration is optimized and upstream and or downstream HEPA or ULPA filters further protect operators from harmful dust exposure. The standard manometer indicates when the main filters needs cleaning, taking the guesswork out of service intervals. A manual motor starter is also standard, highly visible and easy to use.

- Continuous duty, 4.6 kW side channel blower

- 12.2 gallon collection container

- Four conical cartridge filters

VHW440-InfiniClean

The VHW440 InfiniClean delivers the features and performance of the VHW440, but with continual, automated filter cleaning. It is the perfect solution when collecting fine dry dusts in a production process without the need to stop the machine.

The VHW440 IC continuous duty vacuum is fully prepared to go to work, with a manometer, motor starter and fully enclosed chassis. The main filters are cleaned on a continuous cycle while the machine is running, using the vacuum’s own exhaust air to reverse purge the cartridges. With almost 27 sq ft of surface area, filtration is optimized and the standard downstream or optional upstream HEPA filters further protect operators from harmful dust exposure. The standard manometer indicates when the main filters need replacement, taking the guesswork out of service intervals. A manual motor starter is also standard, highly visible and easy to use.

- Continuous duty, 4.6 kW side channel blower

- 12.2 gallon collection container

- Five conical cartridge main filters