Active Explosion Suppression Systems

Active Explosion Suppression System Design & Integration

breadcrumb >> list

The Right Suppression System for Your Company

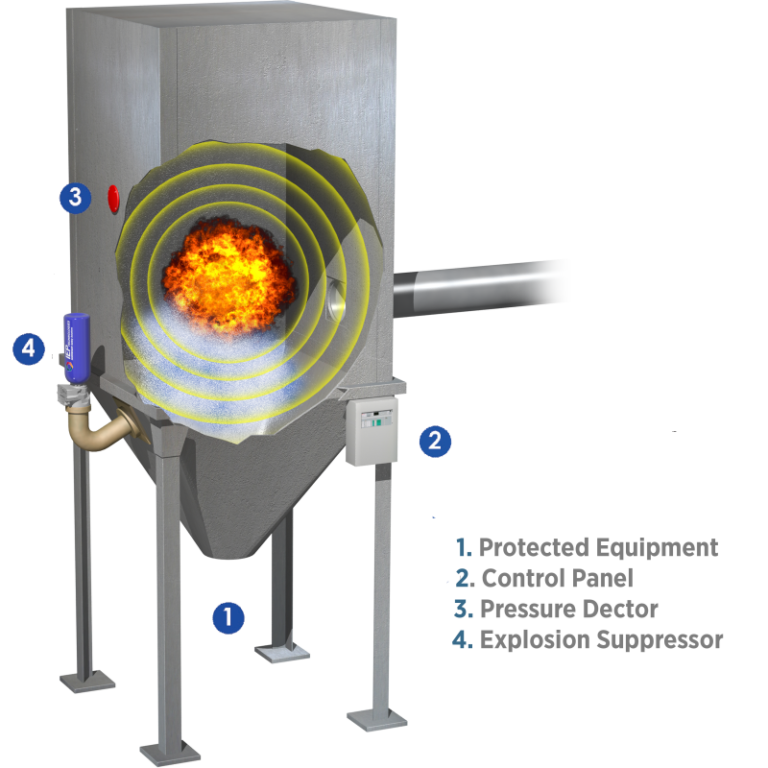

An explosion suppression system consists of three components: a detector; control unit; and suppressor(s). In the event an ignition occurs, the fireball expands from the ignition kernel with the pressure wave (created by the increase in temperature) traveling ahead of the flame front. Explosion pressure detectors are configured to respond to the characteristic pressure increase within milliseconds.

The explosion suppression control unit receives the detection signal from the pressure sensors and sends a release signal to the explosion suppressor(s). Suppressant is injected into the protected vessel at high rate and high velocity, using specially designed nozzles to disperse the suppressant and engulf the growing fireball. This rapidly cools the fireball, mitigating further combustion and reducing the explosion pressure. Integral to the design of most explosion suppression systems is a chemical or mechanical explosion isolation system to reduce the risk of flame/explosion propagation to other connected process equipment.

Dust Collector Explosion Suppression Systems

Dust collectors are typically used as receiving vessels or for the collection of dust. They separate dust from the air stream by employing an array of filter bags or filter cartridges. Dust-laden air slows down as it enters the collector, shedding some of its dust load into the collection hopper which may empty via a rotary gate valve. The lighter dust is swept up into the filter components from which it is periodically removed by air blasts or by a shaker mechanism.

Spray Dryer Explosion Suppression Systems

In a typical spray drying system an organic aqueous slurry enters the drying vessel via a spray nozzle. As the atomized cloud of material falls under the influence of gravity, an incoming stream of hot air dries it. The dried material leaves the hopper section

where it may be further dried or cooled by a fluid bed dryer/cooler before entering a dust separator such as a dust collector or a cyclone (as shown). Multiple separators may be used.

Milling Systems Explosion Suppression Systems

Milling applications cover a broad range of equipment types. The illustration shows a pin mill. Material passes down an inlet duct to the center of the mill from where it is thrown outwards to impact opposing sets of overlapping pins. One set of pins stands upon a fixed plate, the other set stands upon a rapidly spinning disk. Collisions between particles, and between particles and pins, creates a very fine material which is conveyed into an adjacent collector.