Hazard Monitoring for Grain Elevators

A modern and dynamic safety monitoring system

This modern system is dedicated to protecting your bulk-handling machinery at all times. The M-Jet System can be accurately set to monitor, manage, and analyze all defects, and report on the productivity of your machines in real time. Information can be accessed day or night directly to your laptop, tablet, or mobile phone. This complete range of hazard monitoring and safety equipment can handle facilities with up to 120 conveyors giving our customers the most economical solutions available on the market today.

breadcrumb >> list

BOSS Products for Conveyor System Hazard Monitoring

M-Jet Hazard Monitoring Devices

M-JET SYSTEMS are specifically designed as an early warning system to alert facilities to potential sources of explosion ignition. The hazard monitoring devices are able to accurately monitor, manage and analyze productivity, operating conditions and hot-spots that could lead to additional equipment damage, costly repairs and explosion hazard. Data Reports include dangers associated with speed control, misalignment, level & choke control, bearing and motor temperatures.

Motion Controller

VIGIRO IP26 & VIGIRO SV26

Boss Products offers two options for the motion controller engineered to control the constant speed of a rotative shaft. It is frequently installed on buckets’ elevators, chain conveyors, mixers, locks, etc.

The VIGIRO IP26 is an INTEGRATED INDUCTIVE DETECTOR with a Vmax of 500 rpm. VIGIRO IP 26 devices can be connected directly to a central control area or to the hazard monitor M-JET+. Quick fitting to the shaft, the sensor requires only a M12 mounting bolt (M10 optional) and features an anti-rotation flexible strap. Two options of the VIGIRO IP26 are available.

The VIGIRO SV26 is an INTEGRATED INDUCTIVE DETECTOR with a Vmax of 500 rpm which detects 6 to 6000 pulses/min. Preset under speed settings include -33/-20/-11/-6 %. Quick fitting to the shaft, the sensor requires only a M12 mounting bolt (M10 optional) and features an anti-rotation flexible strap. Two options are available. The VIGIRO SV26 IS NOT usable with the M-JET+ Hazard monitor.

Available Models

VIGIRO IP26 – Rotation speed sensor : ATEX (II2D) IP67 T 80°C

VIGIRO IP26 – Rotation speed sensor: IP67 T 80°C

VIGIRO SV26 – Rotation speed sensor: ATEX (II2D) IP67 T 80°C

VIGIRO SV26 – Rotation speed sensor: ATEX IP67 T 80°C

Dustproof Belt Alignment System

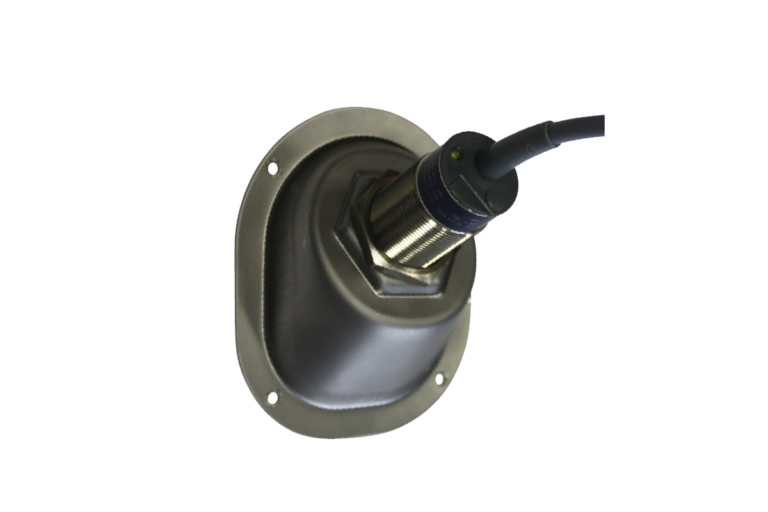

VIGIBELT® TOUCH & VIGIBELT CDM80C®

The VIGIBELT® TOUCH is a lateral movement sensor that detects run-out of elevator belts or conveyor belts, and at the same time the run-out of the lift pulley. It reacts to the pressure of the belt coming into contact with the front face of the sensor. Baffle plates are usually fitted opposite each other, preferably on the upward leg close to the pulleys for elevators, and on the load bearing side close to the drums for conveyors. The sensors, which trigger when the belt applies a force of approximately 5 daN, can be connected directly to a PLC, or for absolutely safety, to an independent “monitoring M-JET” central unit. The electrical circuit can control an alarm or a machine shut down. For elevators more than 20 meters long, we recommend fitting the head with a second VIGIBELT® TOUCH kit, still on the upward leg.

The VIGIBELT CDM80C® is an elevator belt alignment system which has to be placed on an elevator in order to avoid any friction between the belt and the inner sides of the elevator’s leg. The CDS80C VIGIBELT® has to be installed by pair on the going-up leg, above the elevator’s foot. As far as elevators higher than 20 meters are concerned, the head also has to be equipped on the up-going leg. One or several targets also have to be installed on the elevator’s belt (at about every 30 meters) to enable an even more accurate control.

Bearing Temperature Sensor

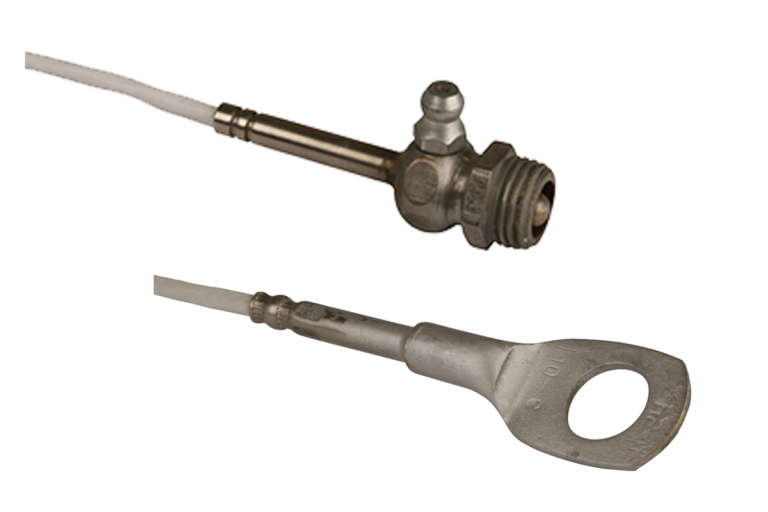

VIGITHERM GST100 LG & VIGITHERM GST100 HX

The VIGITHERM GST 100 LG is a PT 100 Class B ATEX Certified bearing temperature sensor that can be connected directly to a central control area or to the hazard monitor M-JET+. Rated for ATEX Zone 21, Dust, the sensor requires connection through an intrinsic safety barrier for use in ATEX zones. PT100 sensors require connection to an appropriate signal conditioning device, a 1/4 inch grease fitting adapter, and a 10M Teflon coated and braided cable. Operating temperature is 250°C .

The VIGITHERM GST 100 HX is a PT 100 Class B ATEX Certified bearing temperature sensor that can be connected directly to a central control area or to the hazard monitor M-JET+. Rated for ATEX Zone 20, Continuous Dust, the sensor requires connection to an appropriate signal conditioning device. The lug style terminal attaches to a 1/8 or 1/4 inch grease fitting and a 3M teflon coated and braided cable. Operating temperature is 100°C ATEX / 180°C no ATEX.

Level and Choke Sensors

VIGIMAT DNC 30

The VIGIMAT DNC 30 Level and Choke Sensor is a level indicator and jam capacitive detector. The VIGIMAT DNC 30 devices can be connected directly to a central control area or to the hazard monitor M-JET+.