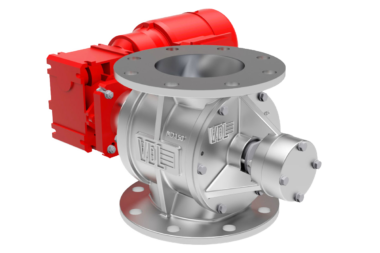

Rotary Valves & Airlocks

Automatically & Continuously Transfers Dust

from the Hopper to the Conveying System or Collection Container

breadcrumb >> list

Rotary Valves continuously transfer dust from the hopper to the conveying system or collection container to create a complete automated dust collection system.

Rotary Valve Types

Rotary valves are designed with a precision seal that keeps air out of the hopper and safeguards the performance of the collector. Capt-Air uses Donaldson Torit Rotary Valves in their designs which are available in either AN, CI or F Series.

Features

- Fast, efficient automated dust collection and disposal

- Continuous dust disposal that keeps hopper and collector operating at peak performance

- Reduced dust collector maintenance time and cost

- Trustworthy, high quality technology from the leader in industrial air filtration

FT Rotary Air Locks

Capt-Air uses Donaldson Torit FT Rotary Valves. These rotary airlocks are an excellent choice for dust collector and cyclone-based collection systems. The flexible tip design allows the airlock to handle stringy or fibrous products that can jam other types of airlocks. The FT Rotary Valves flex tip material is excellent for abrasive applications such as glass cullet and other natural minerals.

Features

- The Donaldson Torit FT series airlock is an excellent choice for most dust filter and cyclone applications

- The flexible tip design allows the airlock to handle stringy or fibrous products that jam other types of airlocks

- Typical materials include paper, wood products, animal feed and other agricultural products

- The flex tip material is also excellent in abrasive applications such as glass cullet and other natural minerals

VLD Series Rotary Valves

Capt-Air uses BOSS Product VDL Series of rotary valves for bulk handling applications. These rotary valves are specifically made for use in material handling applications where high heat, high vacuum, large pressure differentials, fine powders or low-pressure applications are a consideration.

Features

- VDH-HTHB Typically used as a rotary airlock for dust collectors and cyclones, the heat resistant VDL-HTHB Rotary Valve can also be used as a feeder valve for screw conveyors, scales, dryers, and coolers.

- VDL-HTSHB Ideal for dust collectors, cyclones, silos, hoppers & specialized process applications, this rotary valve is tested for high vacuum applications up to 160” WG. It has rotor selections for dry, corrosive & sticky materials.

- VDL-HT Rotary Valve is typically used for handling light powders and granules.

- VDL-HTS is typically used as a rotary airlock in high vacuum installations. Suitable as a dosing lock under silos and bunkers for pressure differentials up to max. 0.5 bar and products with normal flow characteristics.

- VDL-MD is typically used as a rotary feeder for filling processes and pneumatic conveying and for dosing applications of powders and granulates. The medium duty lock has been specially developed for pneumatic transport and can be used in installations where low pressures are used.