Explosion Vents & Flameless Vents

breadcrumb >> list

Flameless Vents

Iv8 Flameless Explosion Relief Vent

The IV8 Flameless Explosion vent provides an explosion protection solution for process vessels that are located inside a building or areas where standard explosion venting cannot be safely employed. For these applications, flameless explosion vents may be the best protection solution. When an explosion occurs, the venting device opens and vents the explosion pressure and flame through a flame arrester, thereby cooling the hot gases and quenching the flame. The IV8 utilizes a stainless steel explosion relief vent and flame-arresting mesh enclosed in a durable carbon steel coated frame. The integrated vent burst detection sensor allows plant personnel to respond accordingly in the event of an explosion within the protected application.

EVN 3.0 Explosion Relief Valve

Many process vessels are located inside a building or another area where standard explosion venting cannot safely be employed. For these applications, flameless explosion vents may be the best protection solution. The EVN flameless vent consists of a venting device with an integrated flame arrester. When an explosion occurs, the venting device opens and directs the vented explosion through the flame arrester, where gases are cooled as they pass through the flame arrester material thus preventing flames from being expelled to the surrounding areas. The integrated electronic controls keep plant personnel informed of the status of the system.

Explosion Refief Vents

Bess-Ex® Vent for Battery Energy Storage Applications

Typically the most cost-effective option in terms of installation and maintenance, IEP Technologies’ Passive Protection devices take the form of explosion relief vent panels which safely divert the deflagration to a safe place (atmosphere) and in doing so prevent the rapidly developing explosion pressure from causing container rupture, structural damage, and possible injuries to personnel. Vent sizing is based on a number of different factors, including explosivity characteristics of the vapors that may be off-gassed from the specific type of batteries, container strength (including door latches and hinges), opening pressure of the vent panels, and free area atop the storage unit for vent panels to reside. A qualified professional should be used when determining the size and quantity of vent panels to be used for BESS units and various designs, sizes, and profiles are available to suit all installations and locations, including “flameless venting” devices if the explosion cannot be safely vented to atmosphere.

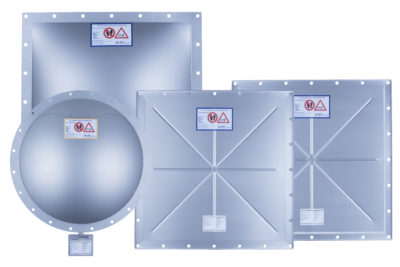

Explosion Venting Solutions

IEP Technologies Explosion Vent Panels are designed to minimize damage to process vessels, ducts, and other industrial structures in the event of a deflagration involving combustible materials. They are relief devices designed to rupture at a predetermined pressure, allowing the fireball and pressure from a deflagration to vent into a safe area. These highly efficient vent panels fit into the walls and sometimes the roof of a process vessel, and are available in a variety of sizes, configurations, ratings, and materials to suit specific applications. Styles include rectangular or round, domed or flat vent panels. Options include insulated vent panels and burst sensors for an indication that a vent panel has ruptured.