Explosion Isolation Devices

breadcrumb >> list

Explosion Isolation Devices

High-Speed Isolation Valve

The High-Speed Isolation Valve provides a solution for vital explosion isolation applications. It operates in milliseconds to provide a mechanical barrier within a pipeline. The High-Speed Isolation Valve has a stainless-steel body incorporating a fully ported stainless-steel valve gate. The valve is designed to withstand a 150 Psi pressure wave from a deflagration without deformation. Closure is achieved in milliseconds by rapidly discharging nitrogen into a piston actuator. The nitrogen is supplied by an IEP Technologies High-Rate Discharge Bottle. Detection is typically provided by an IEP Technologies explosion pressure detector. The detector is monitored by an IEP Technologies control unit which provides supervision, alarm, system actuation, and process shutdown. Typical applications for the valve include explosion isolation on dust collectors, mills, fans, vapor recovery lines, dryers, and other interconnected process equipment.

IsoFlap™ Passive Isolation Valve

For process equipment mounted outside or close to an outside wall, explosion relief venting is a viable protection method. However, in order to protect the upstream equipment, it is vital that the protection method includes a means to mitigate the propagation of flame and burning materials back upstream. This can be achieved by either using an active isolation system (chemical or mechanical) or by using a passive isolation valve. The passive explosion isolation valve is a self-actuating device, which provides a mechanical barrier to mitigate the propagation of flame and burning materials to upstream equipment. The passive isolation valve provides features unique to this style of valve, including an Accumulation Sensor, Wear Sensor, and Interface Panel.

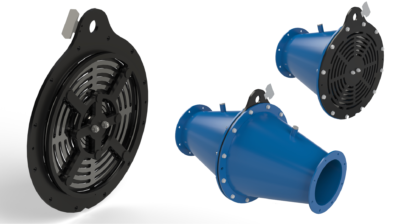

IsoDisc™ Passive Isolation Valve

The IEP Technologies range of passive isolation devices type IsoDiscTM is a cost-effective and reliable explosion isolation solution that mitigates explosion propagation risks to upstream equipment or flame and pressure transmission to the environment. These passive isolation solutions are effective, self-actuating devices providing inlet explosion isolation to protected vessels handling combustible dust, such as air aspiration inlets of mills or clean air pipe ducting connected to equipment where explosive dust is handled.

VENTEX Passive Isolation Float Valve

For process equipment mounted outside or close to an outside wall, explosion relief venting is a viable protection method. However, in order to protect the upstream equipment, it is vital that the protection method includes a means to mitigate the propagation of flame and burning materials back upstream. This can be achieved by either using an active isolation system (chemical or mechanical) or by using a passive isolation valve. The passive explosion isolation valve is a self-actuating device, which provides a mechanical barrier to mitigate the propagation of flame and burning materials to upstream equipment.