Raptor Products

High-performance systems for your industrial safety needs

Raptor Spark™ family of Fire and Explosion Prevention, Fire Isolation and Diversion devices are designed to keep any size facility as safe as possible. Automatic functions include hazard detection, system shut-down, isolation/abort, and extinguishing and/or suppression. Customized systems are programmed based on client specifications and can be as simple or complex as necessary to protect your individual facility.

breadcrumb >> list

Raptor Spark™ Products for Fire & Explosion Protection

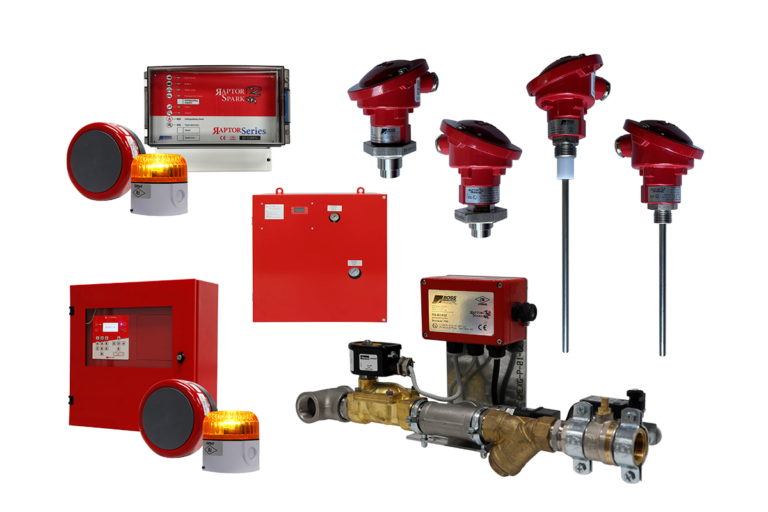

Raptor Spark™ Family of Products

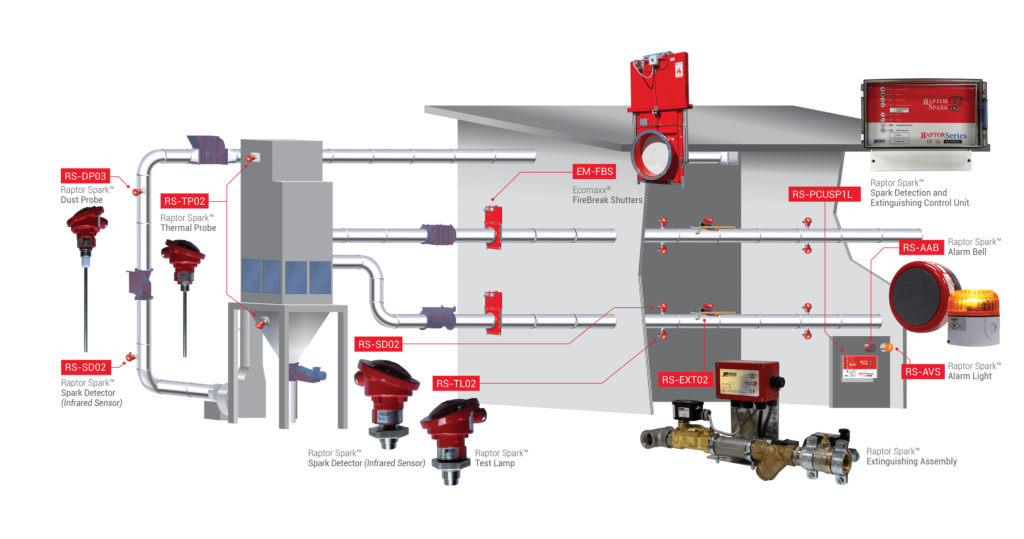

The Raptor Spark™ Detection and Extinguishing System is an FM APPROVED safety device that is designed to detect and extinguish sparks and glowing embers that are travelling through a duct system. The hazard is detected by infrared sensors and extinguished with water spray nozzles within milliseconds of detection. The High Power Raptor Spark™ Detection control module has the capacity to receive hazard alert signals from multiple components (Dust Probes & Thermal Probes) and monitor multiple duct zones and vessels.

Raptor Spark™

The Raptor Spark™ family of Fire Prevention, Explosion Prevention, Fire Isolation and Diversion devices are designed to keep any size facility as safe as possible. Automatic functions include hazard detection, system shut-down, isolation/abort, and extinguishing and/or suppression. Customized systems are programmed based on client specifications and can be as simple or complex as necessary to protect your individual facility.

Raptor Spark™ Detection & Extinguishing Control Unit RS-PCUSP1L

The Raptor Spark Detection & Extinguishing Control Unit RS-PCUSP1L is designed to minimize the risk of fire and explosion in dust filtration and pneumatic conveying systems. This control unit communicates with a variety of components to monitor and protect up to six individual zones. The Control Units RS-CUSP1L & RS-PCU1610SD are FM Approved.

Raptor Spark™ Detection & Extinguishing Control Unit RS-PCU1610SD

The Raptor Spark Detection & Extinguishing Control Unit (RS-PCU1610SD) is designed to minimize the risk of fire and explosion in dust filtration and pneumatic conveying systems. This control unit communicates with a variety of components to monitor and protect up to sixteen individual zones. The Control Unit (RS-PCU1610SD) is FM Approved.

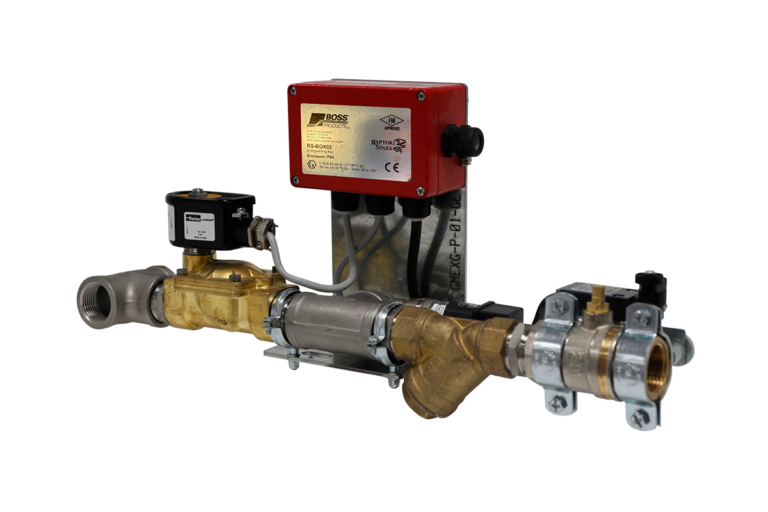

Raptor Spark™ Extinguishing Assembly RS-EXT02

The Extinguishing Assembly RS-EXT02 is designed to work in conjunction with the RS-PCUSP1L control unit and RS-SD02 Spark Detectors. When the control module gets a signal that a hazard has been detected, the extinguishing assembly is activated. A water spray is initiated inside the piping system to extinguish sparks or glowing embers that could cause fire or explosion. The Extinguishing Assembly RS-EXT02 is FM Approved and ATEX Certified.

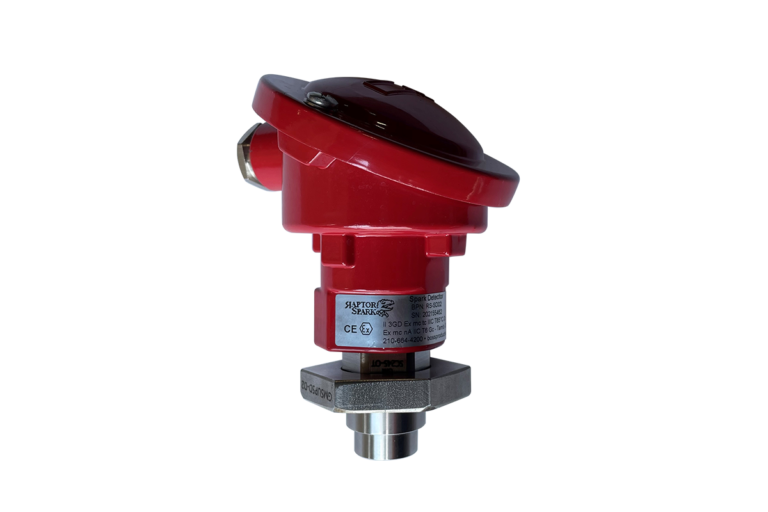

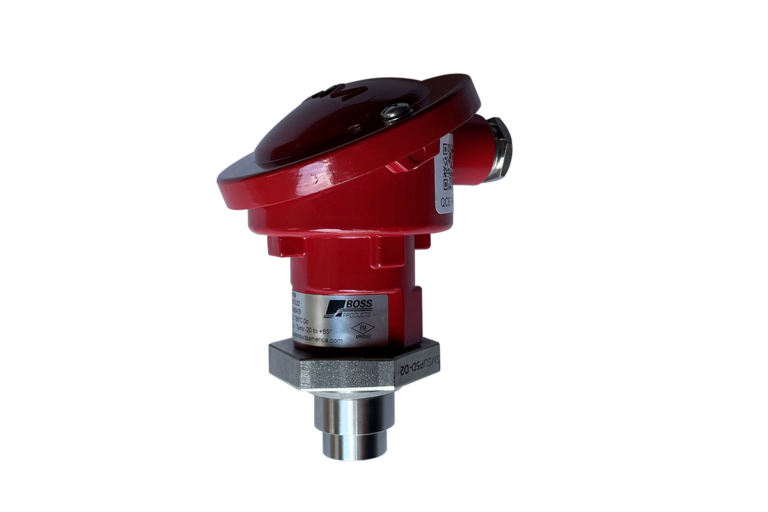

Raptor Spark™ Spark Detector RS-SD02

The Spark Detector RS-SD02 is designed to work with the RS-PCUSP1L Control Unit. The Spark Detector uses advanced technology and circuit, sensitive to infrared light to detect sparks, flames, and incandescent material that passes in front of its optical element. The Spark Detector RS-SD02 is FM Approved and ATEX Certified.

Raptor Spark™ Test Lamp RS-TL02

The Test Lamp (RS-TL02) is designed to work in association with the Spark Detectors (RS-SD02). The Test Lamp provides a function check to ensure the cleanliness of the Spark Detector lenses by emitting high infrared radiation into ducting or pneumatic conveying lines across from the spark detectors to simulate a spark or glowing ember in the line. The Test Lamp (RS-TL02) is FM Approved and ATEX Certified.

Raptor Shield™ (Spark Trap)

The Raptor Shield™ (Spark Trap) was designed with maximum cooling technology that ensures maximum reduction in sparks or burning embers. This device has no moving parts for extremely low maintenance. The spark arrestor is designed to be directly connected to any typical duct connection.

The Raptor Shield™ (Spark Trap) is a critical part of fire prevention in a dust collection system. They help block sparks before they can start a fire. They are a very lowmaintenance and highly effective method that helps block sparks from getting past.

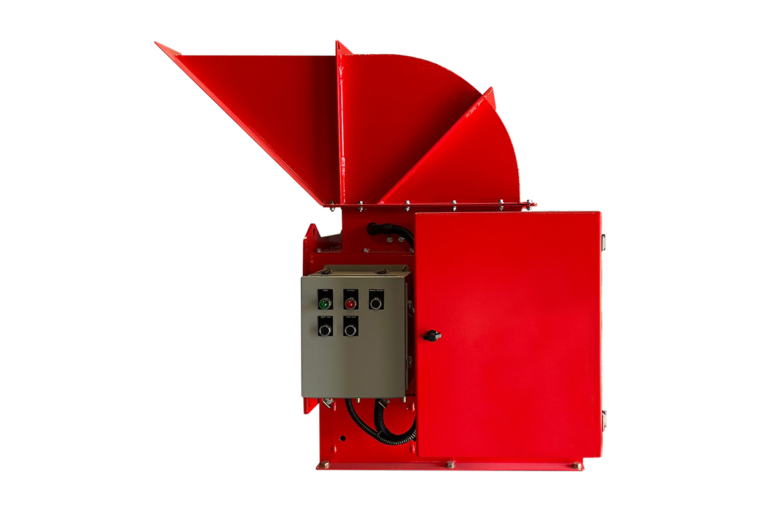

Raptor Gate™ Heavy Duty High Speed Abort Gate

The Raptor Gate™ Heavy Duty High Speed Abort Gate is an important part of any duct spark or leak detection system.

The Raptor Gate™ Heavy Duty High Speed Abort Gate can be located prior to the inlet of a dust collection system to prevent a flame or burning ember from entering the dust collection system. This method is used if your spark detection equipment is not adequate or not an option.

Fire, Smoke, Spark, or Broken Filter sensors can activate the Raptor Gate™ Heavy Duty High Speed Abort Gate in the event of a filter failure or fire.

The Raptor Gate™ Heavy Duty High Speed Abort Gate can be placed on the return air side of the dust collector to redirect contaminated air to a safe location. It is another way to keep personnel and dust collection equipment protected.

Raptor Spark™ Thermal Probe RS-TP02

The Raptor Spark™ Thermal Probe RS-TP02 monitors the temperature rise within a vessel using thermostatic technology. The Thermal Probe is complete with an alarm function which signals upon rapid temperature rise based on fixed threshold set points to monitor the temperature in enclosures. It is designed to be used specifically for fire protection in dust collection systems.

The probes are equipped with a 6”/150 mm long steel stylus that can be placed within the area to be monitored (eg, silos, cyclones, filter units) while the electronic circuit and electrical cable connections remain outside the vessel. These probes have cast aluminum enclosures with IP65 protection. The internal circuit and the measuring sensor (within the stylus) are immersed in a resin bi-component which allows the probe to be installed in difficult places, such as dusty environments. The Thermal Probe is suitable for ATEX zone 22.

Raptor Spark™ Dust Probe RS-DP03

The Raptor Spark™ Dust Probe RS-DP03 is a microprocessor based instrument that is designed to detect and measure dust emissions caused by leaks in filtration media. Design characteristics include precalibrated digital optically isolated outputs and a set of LED indicators.

Operating Principle

The dust probe uses the principle of the displacement of the electric charge in the electrode, induced by the electrical charges, carried by dust immersed in a gaseous fluid.

The amount of electric charge dynamically induced on the electrode is proportional to the amount of dust present in the gaseous fluid. An increase in the concentration of dust, causes a proportional increase of the signal that reaches the microprocessor.

Applying sophisticated mathematical algorithms, the individual powder particles are counted so as to be able to calculate their concentration.

The computed values can be stored internally in order to be drafted in the future, or sent via RS485 serial transmission, or PWM 4/20 mA to an external control unit for further analysis.

Raptor Spark™ Water Pressure Booster Pump RS-CPR

The Raptor Spark™ Water Pressure Booster Pump RS-CPR was designed to regulate water pressure going into the extinguishing unit. It is the best solution for facilities that have over or under pressure water lines available for installation of the Spark Detection and Extinguishing System.