Explosion Isolation & Diversion

Prevent secondary explosions by isolating or diverting the primary event.

Explosion isolation valves should be placed on the inlet, outlet and hopper discharge of protected vessels and interconnecting pipelines to prevent deflagration propagation. Isolation valves are available for a variety of orientations and dust types. Diversion valves are also available with multiple options. Our engineers will work with you to determine the proper valves for your facility and application.

breadcrumb >> list

BOSS Products Explosion Isolation & Diversion Solutions

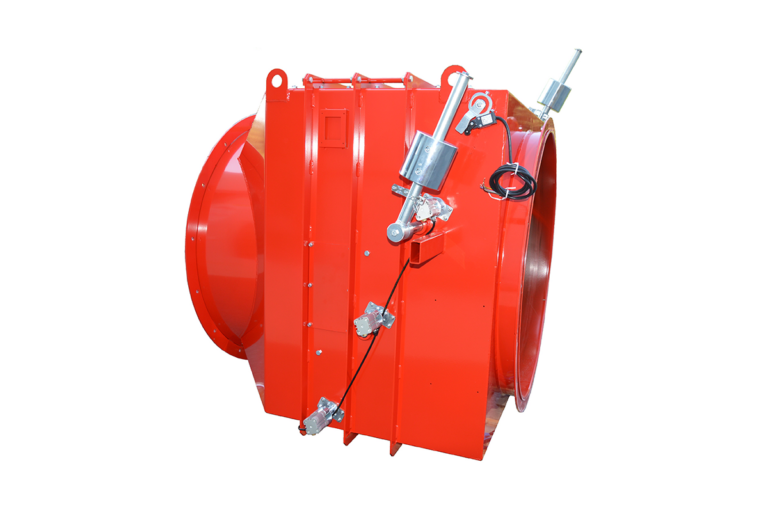

EV-VF VigiFlap Explosion Isolation Valve

The VigiFlap is an explosion isolation valve designed to prevent propagation of overpressure or flame front caused by an explosion downstream in vessels such as dust collectors, cyclones, and filters.

The valve is held open either by air flow or proprietary locking mechanism. As a result, the VigiFlap valve can be used as an explosion isolation device for both the inlet and oulet of a vessel.

The VigiFlap Explosion Isolation Valve complies with NFPA guidelines and is an ATEX Certified device for the containment of explosion.

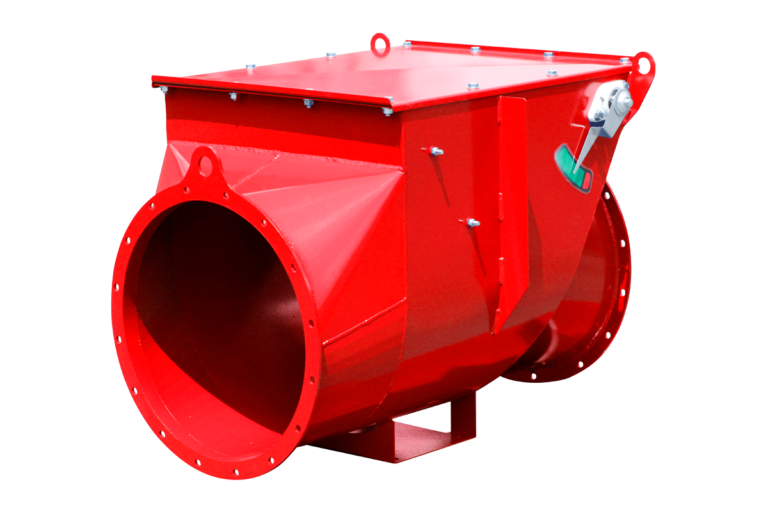

No Return Valve Combo/Metal

The installation of an Explosion Isolation device on all suction side ducts that transport material with a Kst value above zero is an NFPA Requirement.

Installing a No Return Valve Combo/Metal will protect workers and facilities from the damaging effect of a baghouse or filter explosion.

The No Return Valve Combo/Metal is designed for use with all EcoMAXX® High Speed Abort Gates, Fire Break Shutters, Raptor Spark Detection & Extinguishing/Suppression Systems, and Energy Management Systems.

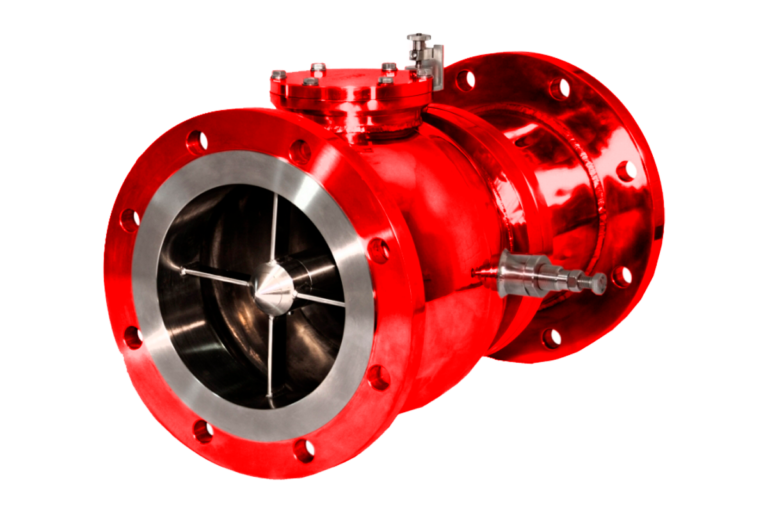

Float Valve EM-FV

The Float Valve EM-FV is designed as an explosion isolation device in air streams with low to low moderate dust concentrations. The maximum allowed recommended particle size is approximately 500 microns. A regular inspection and maintenance schedule is required to ensure that dust deposits that could interfere with the valve’s function are not accumulating.

Explosion Diverter EV-VDIV

The EV-VDIV Diverter Valve with integral explosion panel is the ideal addition to any exterior process flow duct system where there is potential for hazardous explosive overpressure or multiple explosive events. This device helps reduce the potential for system damage caused by high overpressure and rapid flame front expansion.

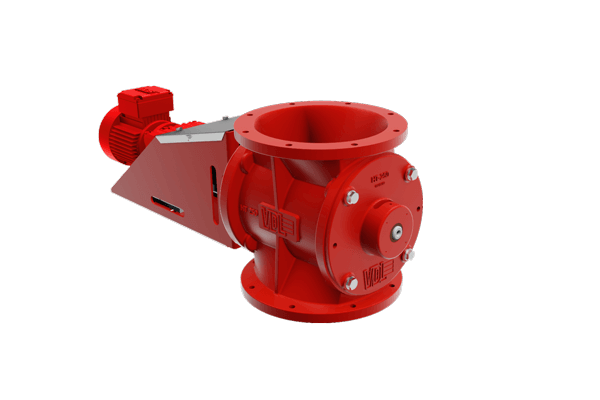

Rotary Valves

Rotary valves for industrial manufacturing are often used to isolate devices when an explosive event occurs in a vessel by isolating that vessel and stopping the flames from propagating and causing secondary events to occur.

Certified Rotary Valve EMVDL-RVEX-HT Datasheet

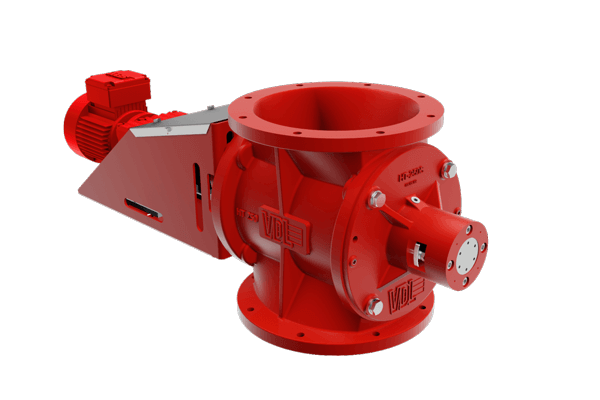

Certified Rotary Valve EMVDL-RVEX-HT

The Certified Rotary Valve EMVDL-RVEX-HT is a rotary airlock for dust collectors and cyclones with differential pressures up to 40” WG.

Applications

- Passive explosive isolation. ATEX EN 15089/NFPA 69

- Differential pressures up to 40” WG

- Rotary airlock for dust collectors and cyclones

- Feeder valve for screw conveyors, scales, dryers and coolers

Certified Rotary Valve EMVDL-RVEX-HTS Datasheet

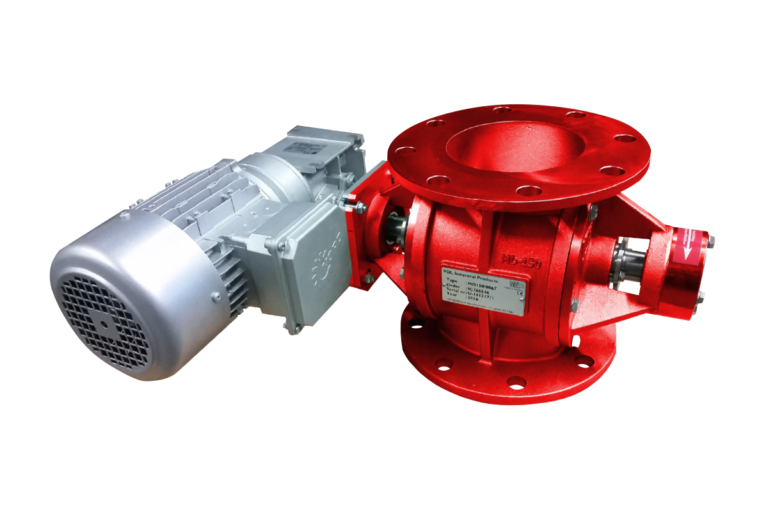

Certified Rotary Valve EMVDL-RVEX-HTS

The Certified Rotary Valve EMVDL-RVEX-HTS is tested for high vacuum applications up to 160” WG. Rotor options are available for dry, corrosive & sticky materials.

Applications

- Passive explosion isolation. ATEX EN 15089 / NFPA 69

- Rotor selections for dry, corrosive & sticky material

- Tested for high vacuum applications up to 160” WG

- Ideal for dust collectors, cyclones, silos, hoppers & specialized process applications

Certified Rotary Valve EMVDL-RVEX-MD Datasheet

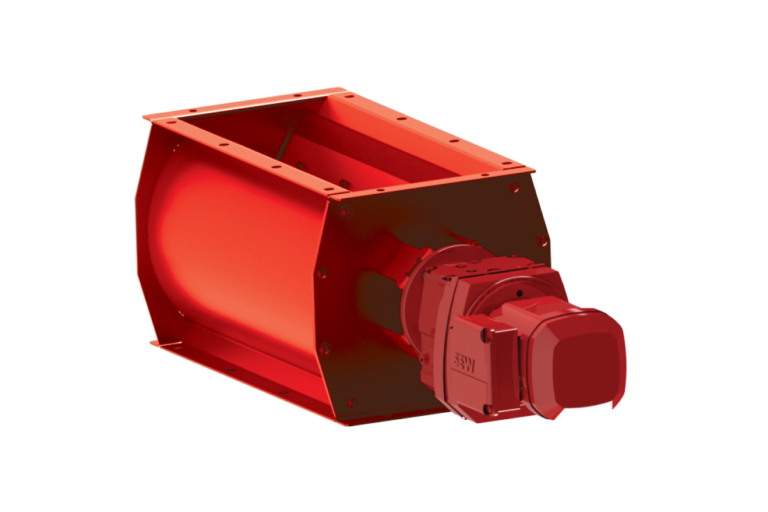

Certified Rotary Valve EMVDL-RVEX-MD

The Heavy Duty Rotary Valve EMVDL-RVEX-MD ideal for high pressure and vacuum applications with differential pressures up to 400” WG. Ideal for the pneumatic conveying of process material.

Applications

- Passive explosion isolation requiring rotor access for frequent cleaning

- Differential pressures up to 400″ WG

- Heavy Duty design is ideal for high vacuum applications

- Recommended for pneumatic conveying of process material and dust feeder valve for screw conveyors, scales, classifiers dryers and coolers

Certified Rotary Valve EMVDL-RVEX-BS Datasheet

Certified Rotary Valve EMVDL-RVEX-BS

The Certified Rotary Valve EMVDL-RVEX-BS is ideal for heavy loading wood applications with differential pressures up to 28” WG.

Applications

- Passive explosion and flame isolation

- Differential pressures up to 28″ WG

- Ideal for wood applications w/flex-tip rotor

- Rotary airlock for dust collectors and cyclones

Raptor Drum™ Explosion Tested Drum KitExplosion Tested Drum KitDatasheet

Raptor Drum™ Explosion Tested Drum Kit

The NFPA compliant Raptor Drum™ Explosion Tested Drum Kit acts as an extension of the dust collector. It is an innovative solution for explosion isolation. No need for wiring, maintenance, motor, starter, wipers, chains.