IEP Technologies eSuppressor™ – An Overview

High-Rate Discharge Explosion Suppressor

Introduction

Explosion protection is essential in industrial safety, especially in industries where dust and vapour pose risks. Capt-Air installs IEP Technologies’ eSuppressor™ to address these dangers. The eSuppressor™ helps reduce the impact of industrial explosions, making it a crucial tool for safety and ongoing operations.

Overview of the eSuppressor™

The eSuppressor™ by IEP Technologies is an advanced explosion suppression system that integrates state-of-the-art sensors and suppression agents to control and extinguish explosions before they can cause significant damage. This device is pivotal in settings where combustible materials are processed or handled, acting swiftly to detect and respond to the earliest signs of an explosion.

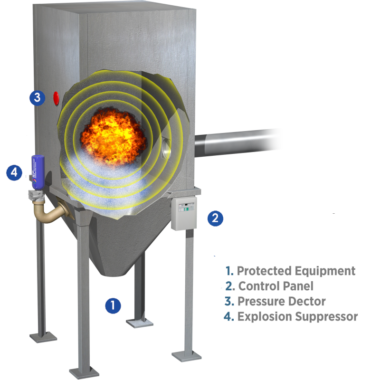

Key Components

The system primarily consists of pressure and optical sensors, a control unit, and strategically placed suppressant canisters. Upon detection of an explosion’s initial pressure wave or optical signature, the control unit activates, signalling the canisters to release a chemical suppressant. This rapid response is crucial for preventing the escalation of the explosion.

Detailed Functionality

To understand the eSuppressor’s functionality, it’s important to consider its two main operational phases: detection and suppression.

Detection

The detection phase is the system proactively and continuously monitors the environment for any signs of an explosion. This is achieved through:

- Pressure Sensors: These sensors monitor changes in ambient pressure, identifying the shock waves that signify the start of an explosion.

- Optical Sensors: Employing infrared or UV sensors, these components detect the unique light patterns produced by flames.

Upon detecting either of these explosion indicators, the sensors relay a signal to the control unit within milliseconds, initiating the suppression phase.

Suppression

Once an explosion is detected, the eSuppressor’s control unit instantly triggers the suppressant release from its canisters. The suppressant, typically consisting of finely powdered material, is dispersed into the area of combustion, where it:

- Absorbs Heat: The suppressant absorbs the heat of the combustion process, rapidly cooling down the environment.

- Depletes Oxygen: It reduces the oxygen level around the flame, starving the fire of its necessary fuel.

- Chemical Inhibition: Some suppressants interfere chemically with the combustion process itself, breaking down the reaction at a molecular level.

The entire detection and suppression process occurs within a few milliseconds, often before the explosion can fully develop, thereby protecting both personnel and facilities.

Applications

The versatility of the eSuppressor™ allows its application across a broad range of industries. These include:

- Pharmaceuticals: Where the handling of powders and solvents can create explosive atmospheres.

- Food Processing: Involving combustible dust from grains and sugars.

- Chemical Manufacturing: Where volatile chemicals and processes pose constant risks.

In each scenario, the eSuppressor™ provides a tailored solution that integrates seamlessly into existing safety protocols, ensuring minimal disruption to operations while maximising safety.

Benefits and Advantages

Implementing the eSuppressor™ in an industrial setting offers numerous benefits, crucial for businesses aiming to enhance their safety standards:

- Enhanced Safety: It significantly reduces the risk of catastrophic damage and injuries.

- Regulatory Compliance: Many industries are governed by strict safety regulations that mandate explosion protection measures. The eSuppressor™ helps in complying with these requirements.

- Cost-Effectiveness: By preventing explosions, the system minimises potential downtime and costly damages to equipment and infrastructure.

Moreover, the peace of mind it offers to both managers and floor personnel is invaluable, fostering a safer, more confident work environment.

Conclusion

IEP Technologies’ eSuppressor™ represents a significant advancement in industrial safety technology. By combining rapid detection mechanisms with effective suppression techniques, it provides a robust defence against the ever-present danger of explosions. For industries dealing with combustible materials, investing in such advanced protection systems is not just a regulatory necessity but a crucial strategy for ensuring long-term operational stability and safety. As safety challenges evolve, solutions like the eSuppressor™ will be vital in safeguarding both human lives and business assets.